Generative Design & Machine Learning

DETAILS

Project MIL mimics nature’s evolutionary approach to design. Designers or engineers input design goals along with parameters such as materials, manufacturing methods, and cost constraints. The software explores all the possible permutations of a solution, quickly generating design alternatives. It tests and learns from each iteration what works and what doesn’t.

The software, developed in collaboration with Airbus, and New York-based architectural firm The Living enables the design of novel bionic airplane parts. A new airplane partition, created through a combination of generative design, 3D printing, and advanced materials is almost 50% lighter and stronger than current designs. This weight savings translates to fuel savings and carbon emission reduction.

LEAD

Carlos Olguin (Autodesk Research)

David Benjamin (The Living)

Sebastian Schäfer (Airbus Innovation)

ROLE

User Research, Design Lead

Bionic Panel

Goal

Cut CO2 emissions of products by 50% by the year 2020.

Strategy

Develop software that allows engineers to design in partnership with AI, leveraging complex algorithms simulating natural phenomena.

Ideation

Initial Interviews with engineers revealed a tendency to explain and sketch design solutions in graph like visuals. Our strategy was to apply those sketch like qualities to a visual programming language.

Solution

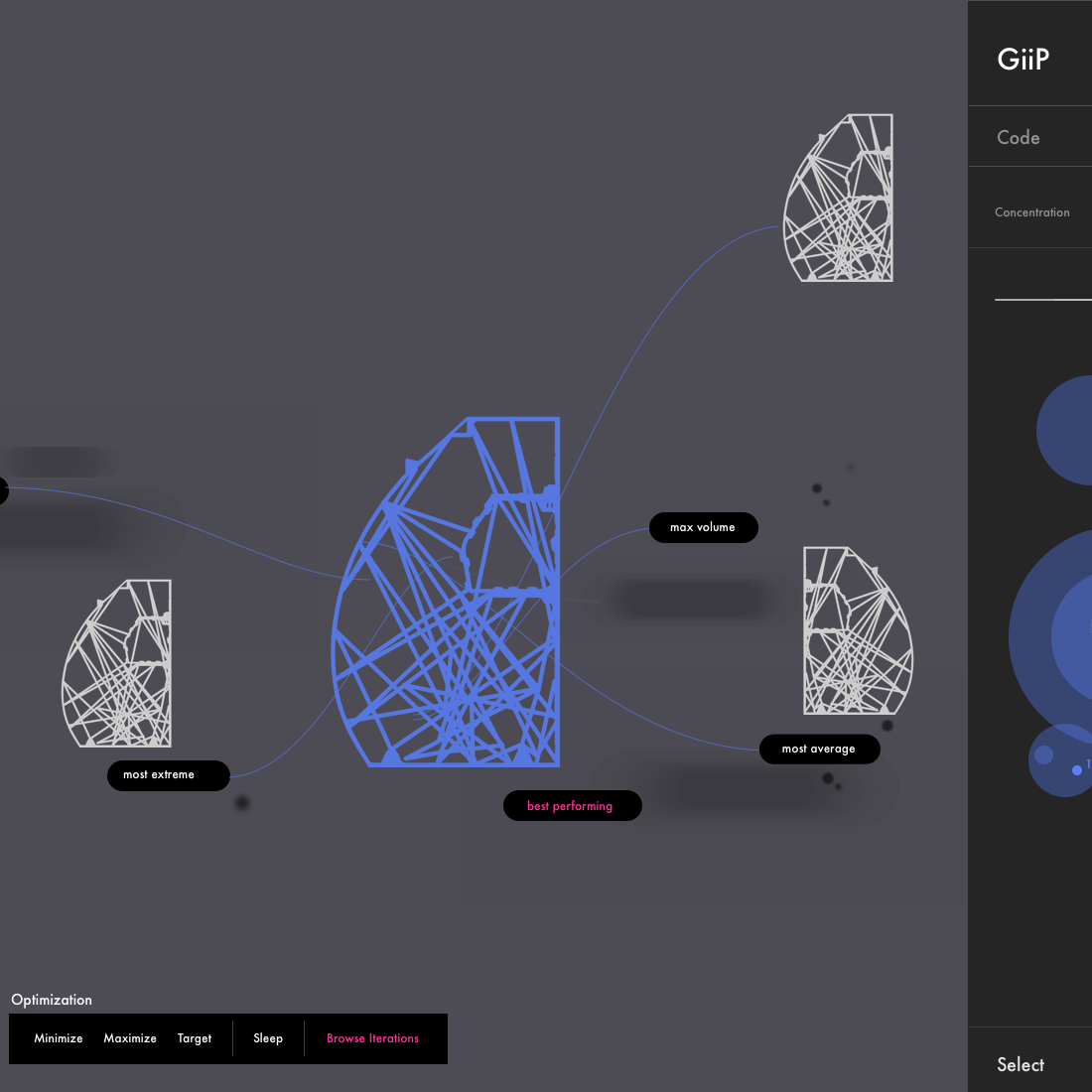

A visual programming environment that allows users to sketch design goals. The environment generates hundreds of possible solutions, trying to match the goals using algorithms simulating natural phenomenons like bacteria, or bone growth. The engineer then selects possible solutions educating the system in his preferences. The AI learns from the user and generates the next generation of solutions, getting closer to a final outcome.

Outcome

After three years of development, the project resulted in a complete, testable prototype of the world’s largest metal 3D printed airplane component. This prototype is currently undergoing 16G crash testing as part of the process for certification and integration into the current fleet of A320 planes. The final design resulted in a 50% lighter airplane part, counting for 166 metric tons of CO2 per year/airplane.